Algorithm by Antti Suuronen, 2020

What have

we done?

Envitecpolis

Smart Platform for Greenhousegas assessments in Farms and Food Industry

Envitecpolis offers calculation and expert services in the areas of energy, finance, and the environment for participants in the food chain. With over 15 years ...

Schaeffler Group

Cost-effective and high-quality wireless condition monitoring.

The Schaeffler Group has been driving forward groundbreaking inventions and developments in the field of motion technology for over 75 years. With innovati ...

Groke Technologies

Streamlining system development by cutting manual work.

Groke Technologies develops intelligent navigation solutions and situational awareness systems for challenging maritime industry needs. The primary market is Ja ...

GOS Group Oyj

High-quality information to support a financing decision.

GOS Group Plc is a fast-growing expert organisation specialised in finance and accounting, founded in 2015. GOS supports its client companies’ management, ...

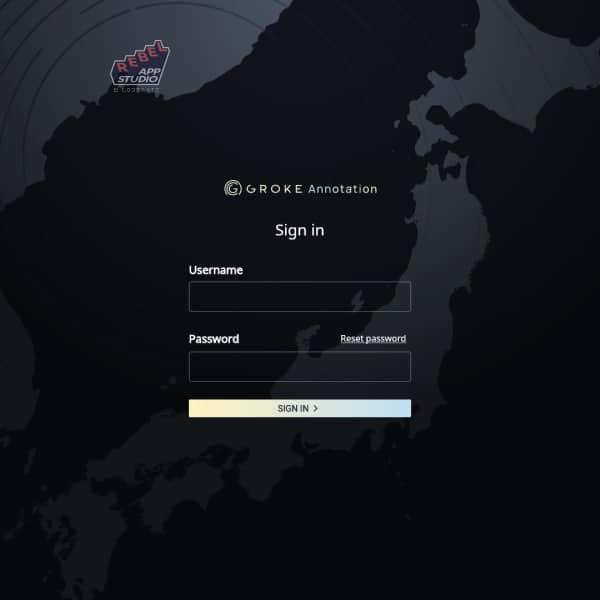

Restel

Developing a loyal customer app in just three months.

The Burger King app was created quickly. It was designed and developed in close cooperation between the Burger King and Codemate teams.

Restel

User-centered design of a restaurant app

With the Food&Events app, users can plan an entire evening of entertainment, including events and meals. The app can be used to order meals at e.g. festivals, ice hockey games, a theatre or a restaurant.

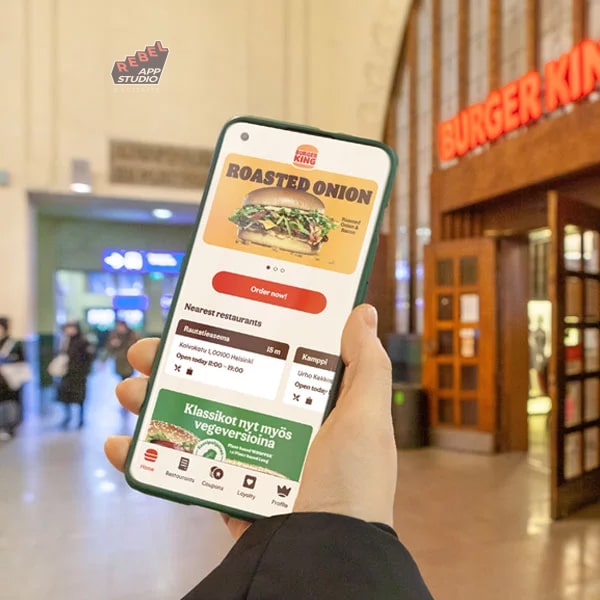

Jutel

Agile renewal of a radio broadcasting system

Jutel is one of the world’s most experienced media and radio automation solution providers. Specialised in radio digitalisation, it offers innovative solutions ...

Edita Prima

Continuous development of a digital asset management service

Edita Prima was founded as far back as 1859. With a mission to help customers communicate better, Edita Prima is a tech company that focuses on customer communi ...

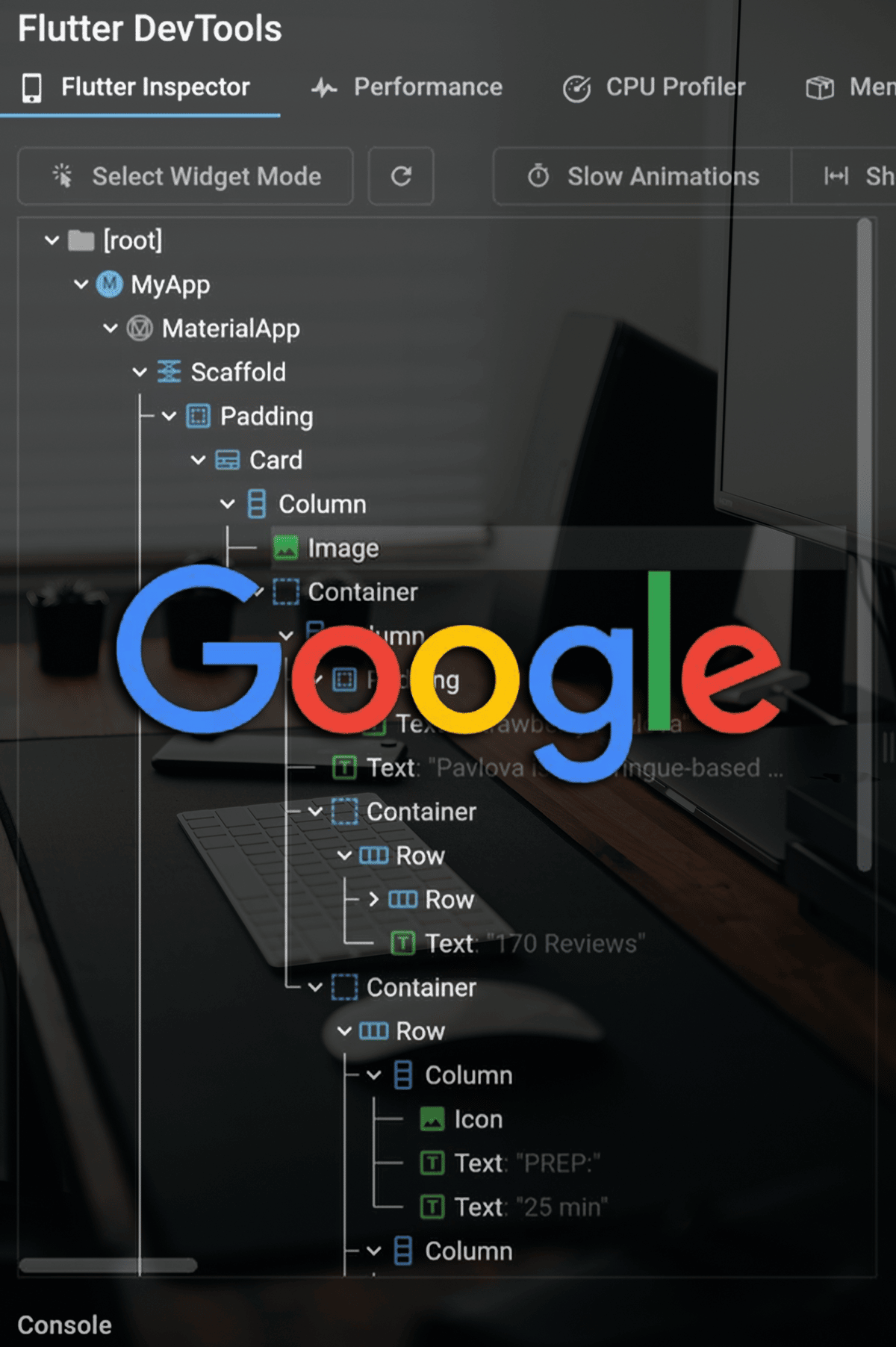

Google Flutter DevTools

Google wanted to improve the developer experience of Flutter applications, by improving DevTools, the main utility tool for Flutter developers. It was getting h ...

Moi Mobile

Mun Moi – operator apps

An application so good that you never have to call customer service. A digital mobile operator challenges the big players with the best digital customer experie ...

Netflix

Netflix data science – Metaflow UI

Netflix improves its recommendation algorithms and predicts the success of new shows by using massive amounts of data. Because managing machine learning pipelin ...

Papua

More proactive work management

Papua is a company that employs around 130 people. Their core business is providing outlet boosting services in the field of retail. Their sales represent ...

Health City Finland

A new way to live

Urban living is changing as we speak. Kotikatu365 (“Home street 365”) is a new living concept created to meet this demand. The concept is developed based on ...

Tradeka

A modern member portal

Tradeka is a Finnish cooperative with nearly M€500 turnover, making good things happen for its 210 000 members and for the surrounding society. Codemate is a di ...